1. Introduction:

In heavy industries such as mining, construction, and material handling, one of the most persistent and costly problems is abrasive wear and tear. Equipment and components that are constantly exposed to friction, impact, and rough materials degrade quickly, leading to frequent maintenance, operational downtime, and increased replacement costs. The demand for a durable, long-lasting, and high-performance wear-resistant material has never been higher. That’s where Abrex 500 Plate comes in.

2. What is Abrex 500 Plate

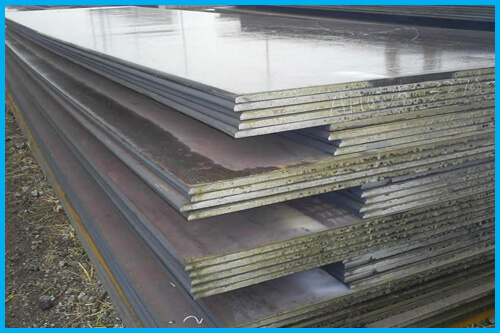

Abrex 500 Plate is a high-strength wear-resistant steel plate manufactured by NSSMC (Nippon Steel & Sumitomo Metal Corporation). Designed specifically to withstand intense abrasion and mechanical stress, this plate features a hardness of around 500 HBW (Brinell Hardness), making it ideal for high-wear applications.

Available in various thicknesses and dimensions, Abrex 500 is engineered to provide superior resistance while maintaining a degree of flexibility, ensuring that the steel doesn’t become too brittle under load or impact.

3. Advantages of Abrex 500 Plate

-

Exceptional Hardness (500 HBW) – Provides maximum resistance against wear and surface damage.

-

Extended Service Life – Reduces frequency of part replacement and increases machinery uptime.

-

Improved Cost Efficiency – Less maintenance means lower long-term costs.

-

High Strength-to-Weight Ratio – Allows use of thinner plates without compromising durability.

-

Enhanced Productivity – Enables machinery to operate longer and more efficiently.

-

Good Weldability & Formability – Despite its hardness, it can be cut, welded, and fabricated using standard methods.

-

Corrosion Resistance – Offers resistance not just to wear, but also to harsh environmental conditions.

4. Real-Life Uses of Abrex 500 Plate

-

Mining Equipment – Dump truck bodies, excavator buckets, and liners.

-

Construction Machinery – Bulldozers, loaders, and crushers.

-

Rail and Transportation – Hopper cars and material handling containers.

-

Agricultural Machinery – Plow blades and cutting tools.

-

Heavy Engineering – Liners, chutes, crushers, and screens in material processing plants.

5. How Abrex 500 Solves the Problem & Product Outcomes

Before the introduction of high-performance plates like Abrex 500, industries suffered frequent breakdowns and short-lived components due to abrasion. By integrating Abrex 500 into their systems, companies have seen:

-

Up to 3x increase in component life

-

Significant reduction in maintenance downtime

-

Lower replacement and labor costs

-

Increased operational reliability and safety

The use of Abrex 500 Plate directly addresses the core issue of material degradation in abrasive environments, delivering a durable, efficient, and economically viable solution.

6. Conclusion

Abrex 500 Plate is more than just a wear-resistant steel—it’s a strategic investment for any business operating in abrasive conditions. With its unmatched durability, excellent performance, and proven real-world results, it is the go-to solution for enhancing the life and productivity of heavy-duty machinery.